WE’RE A FULL SERVICE WIND GENERATOR FACILITY

Zephyr offers a full range of diagnostic repairs including winding analysis, vibration analysis, thermal imaging, and laser alignment. And our extensive coil manufacturing experience will cover all of your wind turbine generator needs.

With our in-house fabrication and machining capabilities, Zephyr Wind Services can diagnose, reverse-engineer, and rebuild or replace a part or component that may be months or even a year lead-time from the OEM. Let’s get your wind turbine back online in a fraction of the time.

OUR MINNESOTA SERVICE CENTER IS DESIGNED FOR THE WIND INDUSTRY

- 51,000 square foot high-bay manufacturing facility

- Additional 16,800 square foot building

- 20 foot overhead door for truck pull-through

- 45,000 square foot shop floor area

- Features 62 foot side walls

- 6,000 square foot rewind clean room

- 3,000 square foot 2-story office & training center

- Overall footprint is 300 feet x 170 feet at our main building

- Additional building is 70 feet x 240 feet

- Located on 7 acres in Hutchinson, MN

BY THE NUMBERS

GENERATOR SERVICES

FULL LOAD VOLTAGE GENERATOR TEST RUN

We test your generator as a generator, not a motor. After testing your generator we provide full test documentation that includes the following:

- Stator volts and amperage

- Rotor volts and amperage

- Axial and Horizontal vibration readings on DE and NDE

- Temperature readings on both bearings

- Full voltage on rotor and stator RPM

- Partial load test to 15% of rated nameplate

GENERATOR EXCHANGE PROGRAM

The only one of its kind in the wind energy industry, our generator exchange program makes receiving a replacement generator for your wind turbine as simple as placing an order. Here’s how our exchange program works:

-

Place an order for a generator to arrive at a specific date and time

-

Zephyr will arrange transportation and deliver your generator to your wind farm

-

The failed generator will come back on the same truck. The failed generator becomes the property of Zephyr Wind Services

-

The failed generator goes through our rigorous 80-page inspection process

-

The generator is then remanufactured and certified, then placed back into the Zephyr exchange inventory

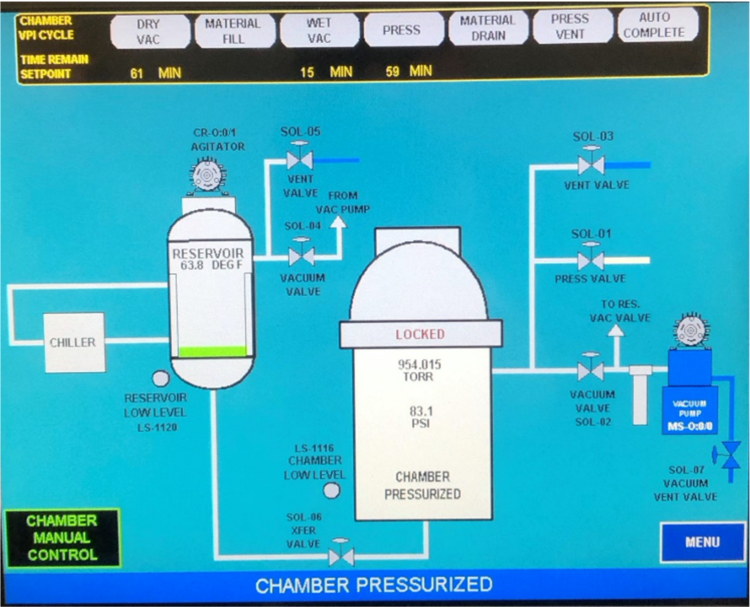

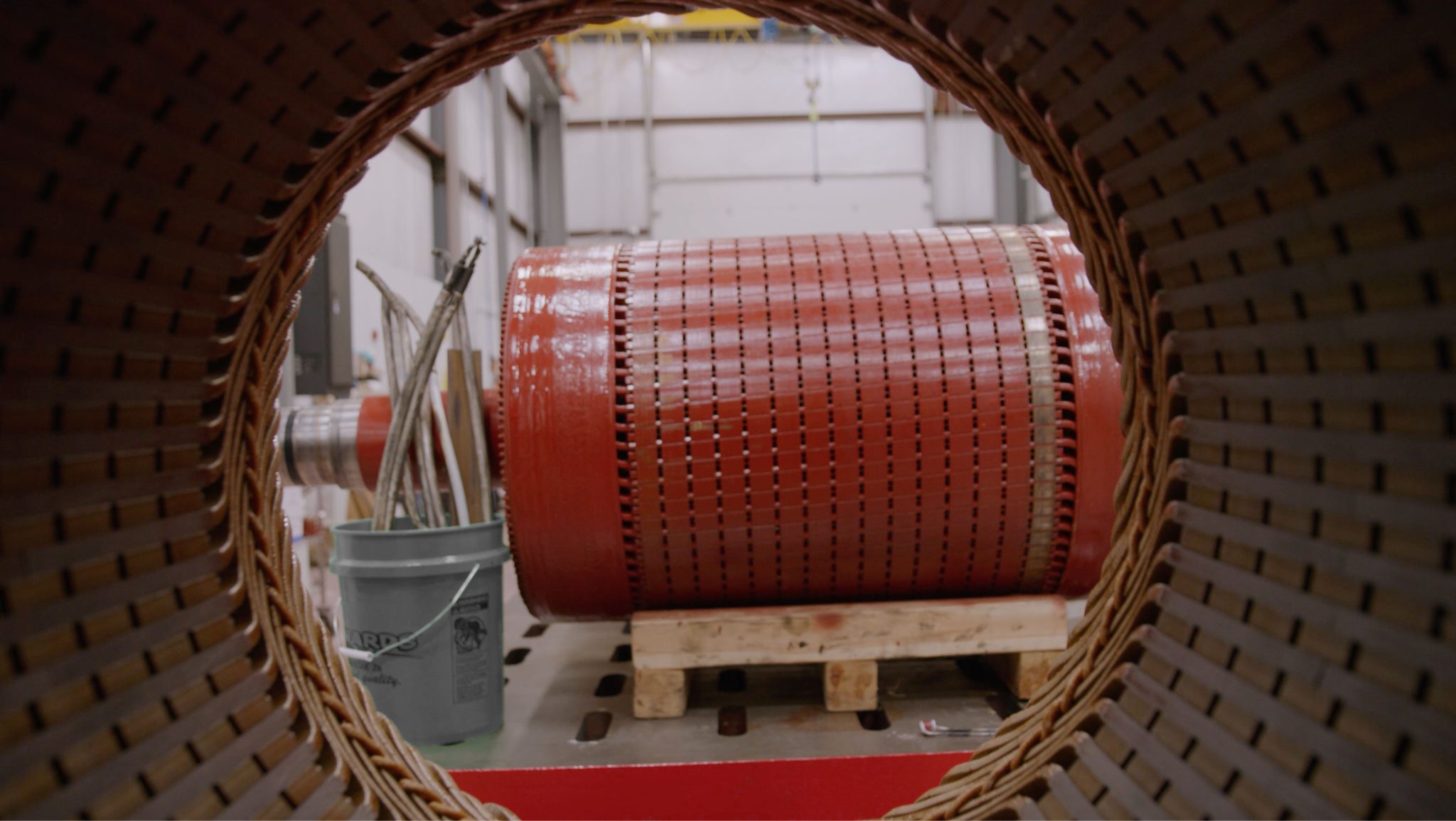

VPI SERVICES

THE MOST STRINGENT VPI PROCESS IN THE WIND GENERATOR INDUSTRY

Our vacuum pressure impregnation (VPI) insulation is ideal for industrial electrical applications such as wind power generators.

PROPRIETARY VARNISH

At Zephyr Wind Services, the rewind process features our proprietary, wind-specific VPI varnish, which is blended to the exact same specifications as those used by OEM generators.

QUALITY CONTROL SYSTEM WITH 100% ELECTRONIC DOCUMENTATION

- All data and pictures sync to the Zephyr cloud

- Pictures, specifications, and schedules are shared with the customer via the website portal

- Every piece of machinery used in the repair or rewind process produces a quality report

- Quality reports are being produced live via the cloud with the wireless employee issued iPad tablets on the shop floor

STORAGE AND MAINTENANCE IN OUR CLIMATE-CONTROLLED BUILDING

Zephyr offers a comprehensive generator management and storage program. For renewable energy companies and OEMs alike, the correct storage space and facility isn’t always available. A storage program helps to keep your overhead low without compromising generator availability.

CONTACT US TO LEARN MOREGENERATOR MAINTENANCE PLANS

Zephyr Wind Services offers customized maintenance plans that are available on a monthly, quarterly, or annual basis depending on your equipment needs.

Get a quote

OEM EXPERTISE

ADDITIONAL IMAGES OF OUR FACILITIES

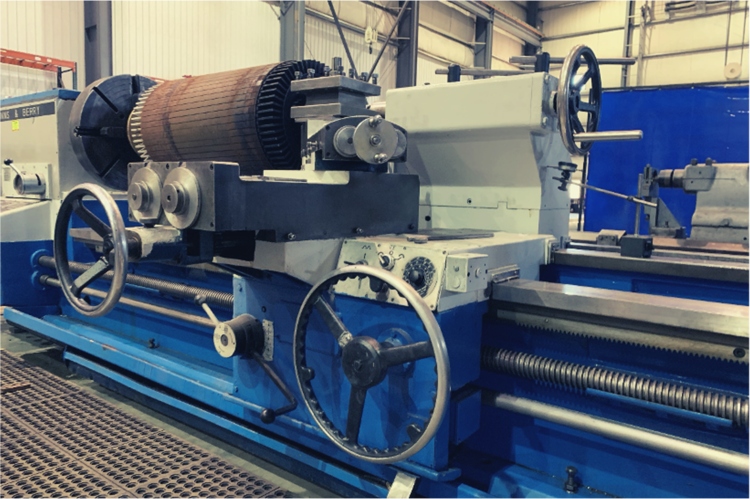

Multiple lathes with Acu-Rite Digital Readouts featuring in-house shaft replacement of re-machining work. Nickel plating of journals.

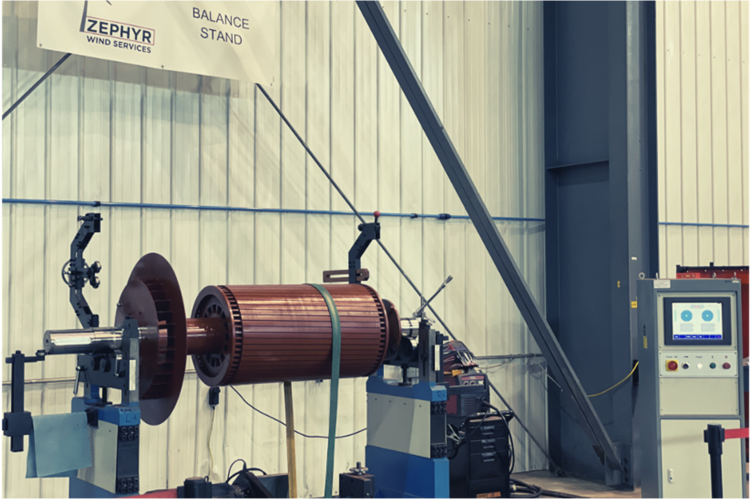

30,000 Pound JL Balance Stand

Calibrated to ISO 2.5 g

We rigorously test all generators that come into our shop with a Baker DX-15 HI POT Tester and a PHENIX Core Loss Tester that’s capable of testing up to 10 MW

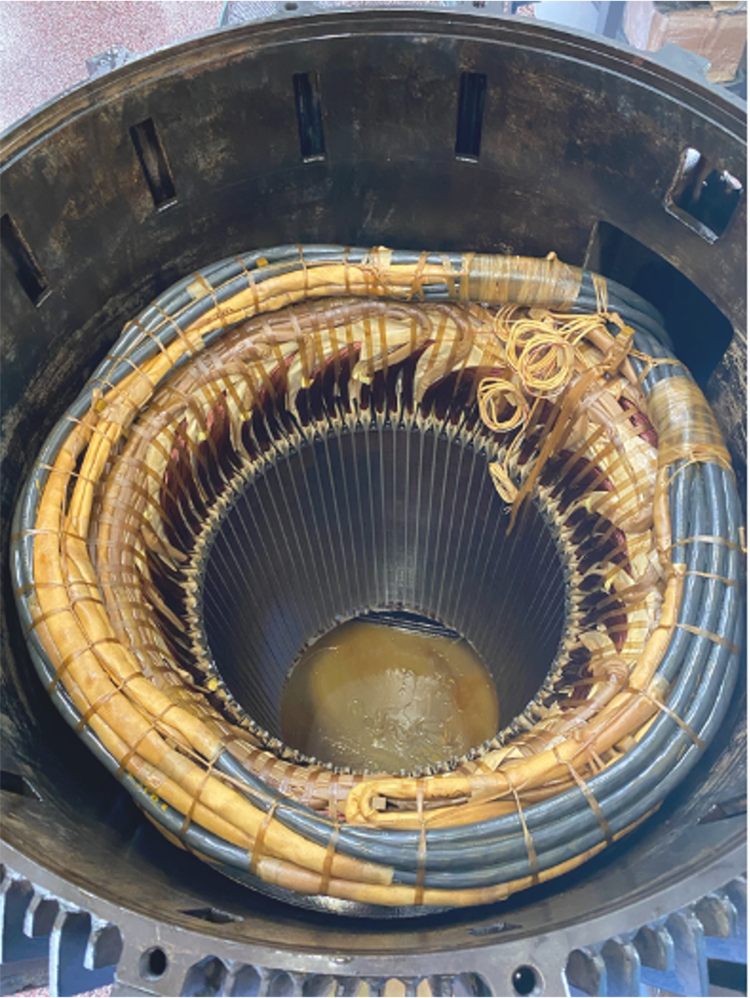

The Zephyr Clean Room is a climate-controlled rewind room with an air exchange system that can handle any kind of repair or rewind

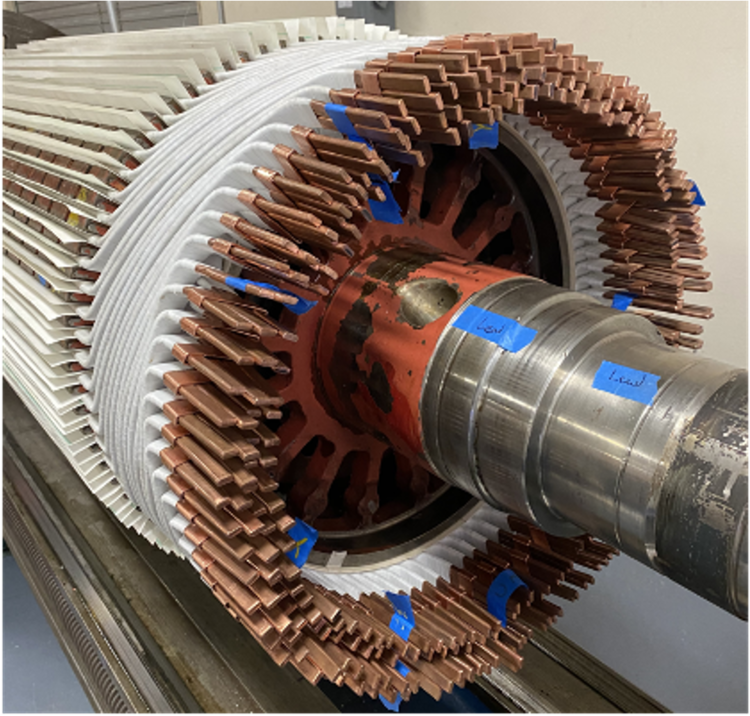

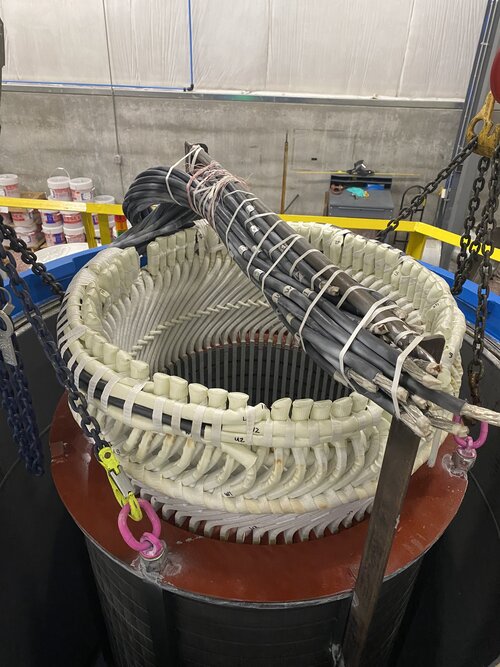

Form Coil Rewind at Zephyr Wind Services

Mush Wound Rewinds

ZEPHYR LOCATIONS